Mechanical testing is a general term for a number of different tests that determine the various mechanical properties of a metal. It is a measure of the response to a loading condition. Midwal Engineering routinely assess mechanical properties, including strength, hardness, ductility, impact resistance, elongation, stress etc.

The following mechanical tests are available:

Tensile testing is used to check the strength and ductility of metals under uniaxial tensile forces. The sample is subjected to uniaxial tension until the point of failure. This test is used to assess Ultimate Tensile Strength, Yield Strength, Reduction of Area and Elongation

Test Methods / Specifications are ASTM E8, ASTM A370, EN 10002-1, ISO 6892-1

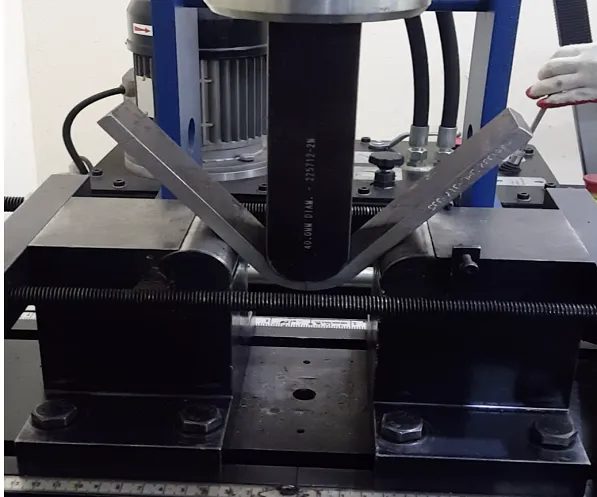

A bend test measures the ductility of a material by bending it over a given radius. It is a simple qualitative test that is used to evaluate the ductility and soundness of a metal.

Test Methods / Specifications are ASTM E190, ASTM E290.

Charpy Impact Testing measures a material’s toughness, the ability to absorb energy, and resistance to brittle fracture. The test involves fracturing notched test specimens at a set temperature with a swinging pendulum. The amount of energy absorbed by the material during fracture is measured.

Test Methods / Specifications are ASTM A370, ASTM E23, ISO 148

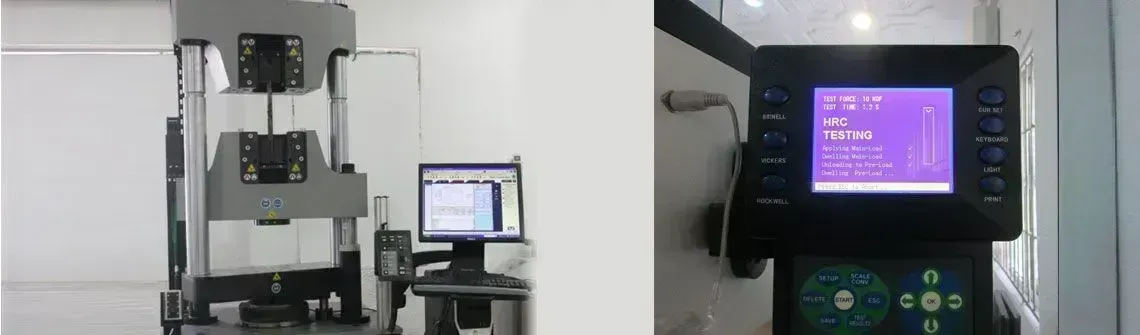

Hardness Testing measures a material’s resistance to indentation. Midwal Engineering offers the following micro and macro hardness tests:

Flattening is a test for the ductility and soundness of pipes when cold pressed between two parallel plates.

Test Methods / Specifications are ASTM A53 and ASTM A370

Our in-house machine shop allows for quick order turn around and ontrol of the quality of test specimens. Equipped with bandsaws, milling machines, lathe and grinders, we are able to prepare specimens in accordance with test specifications and customer specifications. For traceability, each order is Each order is maintained with a unique requisition number that is tracked throughout our facility.