Midwal Engineering assures the integrity of your products and weldments through the following:

Welding and brazing are techniques used to join metals. Welding Procedure and Welder Performance Qualification tests are assessed through some or all of the following tests:

We can test to ASME Section IX, AWS D1.1, API Std 1104, ISO 15614, DNV F101, ABS Rules and other client specific standards

Failure analysis is a multi-faceted, holistic approach to determine how and why a material or product failed. It is conducted to assist in the improvement of product design, the refinement of operational limits, and the implementation of corrective actions.

Based on the type of failed component and its history, Midwal Engineering will perform a root cause analysis to identify the cause of failure. Typically, a failure analysis investigation begins with a collection of relevant background information on the failed part, such as environmental and operating conditions, service records, design details and material specifications. This helps to identify potential threats to the integrity of the component. The scope of testing and analysis is defined and used to collect data which is ultimately used to arrive at a conclusive cause of failure.

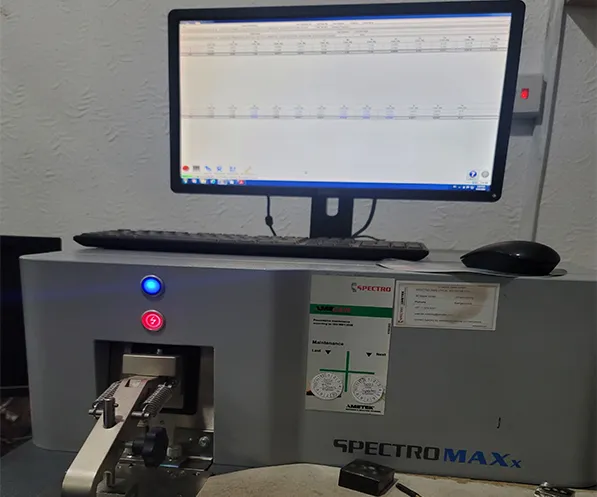

The quality of materials is crucial to the quality of products and the safety of systems. Chemical analysis is performed to measure the precise elemental composition of materials. This is used for specification conformance checks or to identify the elemental composition of an unknown material.

Midwal Engineering performs chemical analysis of metallic materials using the following methods:

Test Methods / Specifications are ASTM E415, ASTM E1086

Test Method / Specification is ASTM E572, API RP 578

Whether you seek to verify a material certification or to obtain a detailed breakdown of an unknown material, Midwal Engineering will provide a Certified Report listing the elements identified and compared to your specification, if provided. We can also identify unknown materials to major material specifications.

Fastener testing allows the determination of the mechanical properties of fasteners. Test specimen can either be a machined specimen or a full-size product.

Test Methods / Specifications are ASTM F606, ISO 898

Steel reinforcing bar (rebar) is embedded in concrete to improve the overall strength of the concrete that surrounds it. Mechanical testing is then necessary to determine if the rebar meets its published specifications, ensuring the quality of the product.

Midwal Engineering can test rebars for tensile, bend and chemical composition according to ASTM A615, BS 4449 and ISO 6935